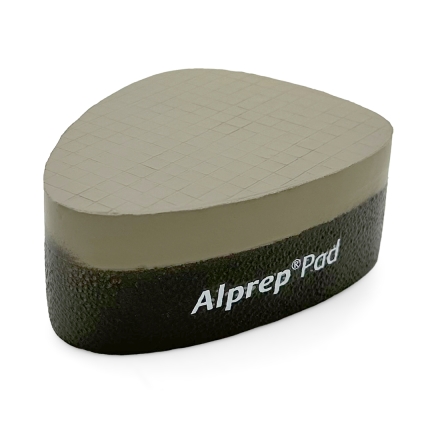

PRODUCT IMAGES SUPPLIED

To create this NPWT stress ball, Medela supplied images of the item, including the dimensions which we used when scaling the item down to be a suitable size as a stress ball. Whilst it was great to have photos and dimensions of the item, we can also work from basic and/or technical drawings too.

HAND SCULPTURED RESIN DESIGN

Our team of highly skilled Master Sculptors used these images and sizes to create a resin sculpture which was scaled to the correct proportions. Images of this sculpture, showing the item from all angles and with full measurements were then provided to the client for approval. At this stage small changes could still be made to the design but the client was happy to proceed with no changes required.

PRE-PRODUCTION SAMPLES

The next stage was to make one off the master tooling for the mould so that we could create a pre-production sample. Any spray masks that were required to colour the item were also created along with the set-ups and printing jigs. Originally only the top part of the pump was to be coloured but the client decided they wanted the bottom part coloured in pantone matched light blue so we added this to the spray mask design. A number of samples were then moulded, coloured and printed for the client’s approval. At this stage the client decided to amend some of the text and add a print to the back and then the item was subsequently approved.

FINAL STAGE - BULK PRODUCTION

With the pre-production samples approved we moved forward with the bulk production and then the final stage of quality control. The clients London event was cancelled due to Covid-19, however the stress balls were very much in demand resulting with us shipping the bulk of the order to Switzerland and the remaining items to the USA. The client was thrilled with the product and was in contact within weeks asking for a quote for a repeat order of a larger quantity.

Client feedback

SEE MORE CASE STUDIES

- SHOW ALL

- ELECTRONICS

- INDUSTRIAL

- TRANSPORT

- CHARACTERS

- ANIMALS

- MEDICAL

- ECLECTIC