BOLLARD IMAGES

The client provided product data sheets to work from and also supplied detailed images of how they needed them to be printed along with the colours to be used. Whilst this was very helpful we can work from simple images or photos when creating a bespoke stress ball.

RESIN SCULPTURE

Using the data sheets our very skilled master sculptors hand crafted the design in resin. Due to the thin area at the bottom of the bollard our team used their expert skill and knowledge to ensure the item would stand when made from foam. Images of this resin sculpture showing the shape from all angles along with full measurements were sent to the client for approval.

PRE-PRODUCTION SAMPLES

Once the resin sculpture was approved we could progress to the master mould and spray masks design. At this stage no changes could be made to the shape, however we manufactured a few fully coloured and printed samples and sent these images to the client so they could see the final product and make any changes to the print if required. The client decided to make a few small tweaks to the spray mask and prints. We duly made these changes and the second pre-production sample was then approved.

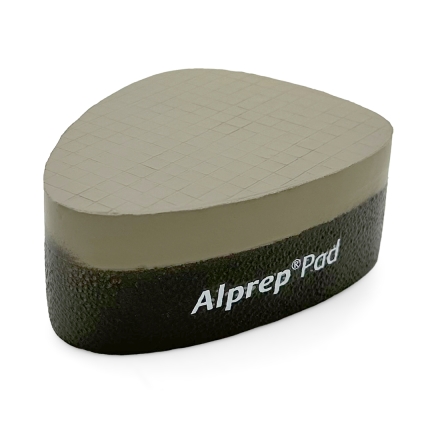

FINISHED ITEM

The bulk of the order was then manufactured, passed through quality control and was shipped to the client. The client was happy with the finished product and said that they went down well with their customers.

SEE MORE CASE STUDIES

- SHOW ALL

- ELECTRONICS

- INDUSTRIAL

- TRANSPORT

- CHARACTERS

- ANIMALS

- MEDICAL

- ECLECTIC