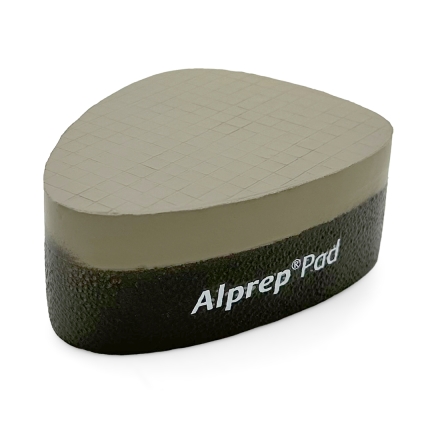

CLIENT SUPPLIED PRODUCT IMAGES

DTS Solutions contacted us as they required a stress ball to be made in a shape of a two way radio that was based on a specific radio model which was then to be customised with their full colour logo on the radio screen.

BASE MOLD DESIGN CREATED

Using a product data sheet for the specified radio we set our master sculptures to work with hand sculpting the basic shape. They used the technical data provided to recreate the details of the radio including intricate carving of the buttons, screen and antennas. The main antenna was shortened for manufacturing purposes as previously agreed with the client. Images of the sculpture along with full measurements were sent to the client which were approved.

MASTER MOULD AND PRE-BULK PRODUCTION SAMPLE

The master mould was then created so that we could create a printed pre-production sample. We do this as whilst no mould changes can be made at this stage we can alter the prints and item/spray colours if required. Images of the samples showing the large logo printed on the radio screen and the button details were then emailed to the client for approval.

BULK MANUFACTURE

As the client was very happy with the sample images we proceeded with the bulk production. The radio’s then were passed through quality control before being shipped to the client well ahead of schedule.

SEE MORE CASE STUDIES

- SHOW ALL

- ELECTRONICS

- INDUSTRIAL

- TRANSPORT

- CHARACTERS

- ANIMALS

- MEDICAL

- ECLECTIC