CUSTOMER SUPPLIED IMAGES

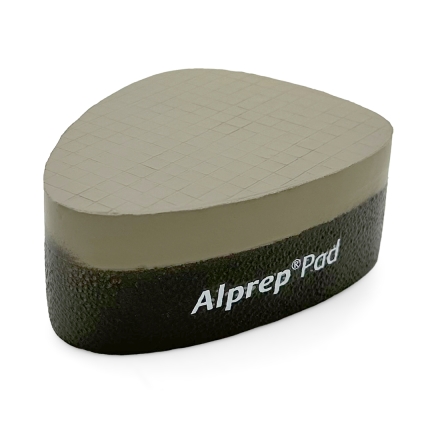

Centek supplied us with CAD drawings of one of their centralisers and asked for a quote to produce 1000 bespoke stress centralisers. The challenge with this shape was the finished stress ball needed a hole down the centre which required it to be moulded in two halves before being glued together by hand.

RESIN MOCK-UP PRODUCED

Using the drawings an initial resin mould is made, photographed with dimensions for approval. Adjustments were made at this stage until the client was happy with the resin prototype.

SAMPLES MADE

With the resin prototype signed off, an initial sample was hand made, sprayed and logo's were applied.

FINAL PRODUCTION

With the sample signed-off and the final tooling made, the manufacturing took place. We made the shape in grey, sprayed the outer in red, and then applied transfer logo prints to the upper and lower sections. This was a highly technical stress shape to produce.

Client feedback

SEE THE FINISHED STRESS BALL VIDEO

SEE MORE CASE STUDIES

- SHOW ALL

- ELECTRONICS

- INDUSTRIAL

- TRANSPORT

- CHARACTERS

- ANIMALS

- MEDICAL

- ECLECTIC