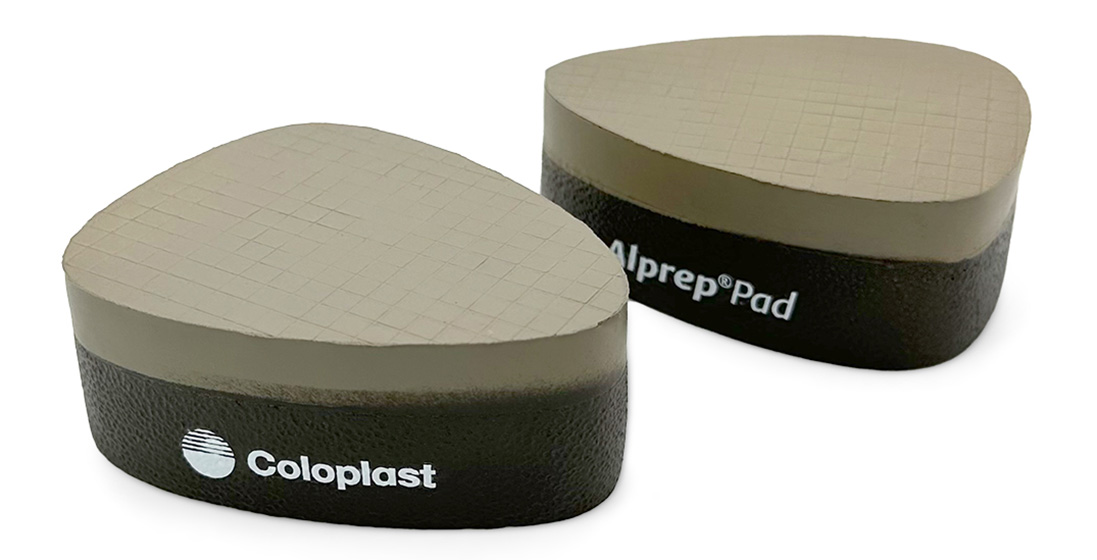

PRODUCT IMAGES SUPPLIED

Images of the Alprep pad were supplied and we were able to quote. The item was to be made similar in size to the actual sponge, with the Alprep Pad logo on one side with the company logo on the other. The order was quickly confirmed for a large quantity and an Alprep Pad was sent to the factory to help with moulding, as we needed to ensure that the base part looked like a sponge in texture.

HAND SCULPTURED RESIN DESIGN

Our master sculptures then used this to hand sculpt the replica pad out of resin. Images of the resin sculpture were sent to the client for approval and with no changes to the design required we proceeded with the master tooling.

PRE-PRODUCTION SAMPLES

With the tooling completed we started on creating a printed sample. The client didn’t have any specific pantone colours for the two shades of grey for the foam so we matched these to a similar colour to the actual product and printed the white logos on either side. Photos of the printed samples were approved and we proceed with the mass production of the alprep pad stress balls

FINAL STAGE - MASS PRODUCTION

Due to Covid 19 and limited air travel we did have some delays with the shipping, the client was kept updated throughout and we managed to get these shipped and delivered to the client in plenty of time for their planned events.

SEE MORE CASE STUDIES

- SHOW ALL

- ELECTRONICS

- INDUSTRIAL

- TRANSPORT

- CHARACTERS

- ANIMALS

- MEDICAL

- ECLECTIC