CUSTOMER SUPPLIED SKETCH

BiB contacted us to create a bespoke stress elbow rest. All we needed was a sketch with some dimensions and it was over to the studio to create a visual

3D VISUAL CREATED

Using the sketch an accurate digital 3D visual was created. The visual document could be rotated, so you can see all the angles of the product, prints and dimensions so the client could be sure the mould would be correct before we went to mass production.

TOOLING PRODUCED

Once the 3D visual was approved, a rapid prototyped male mould was cast. From that prototype the master two part moulds were created. The moulds are made in two parts, then the foam coloured and injected, the two parts of the mould are placed together, the foam expands inside and then the stress ball is ready for printing! Sounds easy, but it's not quite as straight forward as that!

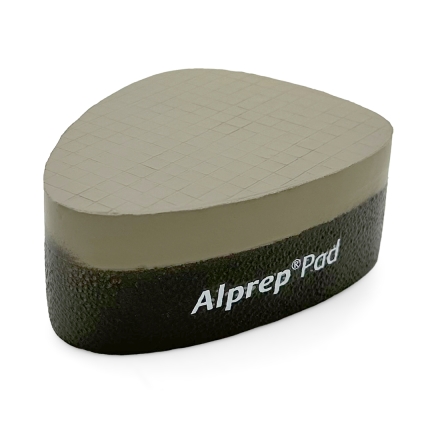

FINAL PRODUCT IMAGES

And the final product looks like this! A great finished stress elbow rest in pantone matched foam for lens examinations. Printed with a high quality flexible transfer print on all four sides.

Client feedback

SEE THE FINISHED STRESS BALL VIDEO

SEE MORE CASE STUDIES

- SHOW ALL

- ELECTRONICS

- INDUSTRIAL

- TRANSPORT

- CHARACTERS

- ANIMALS

- MEDICAL

- ECLECTIC