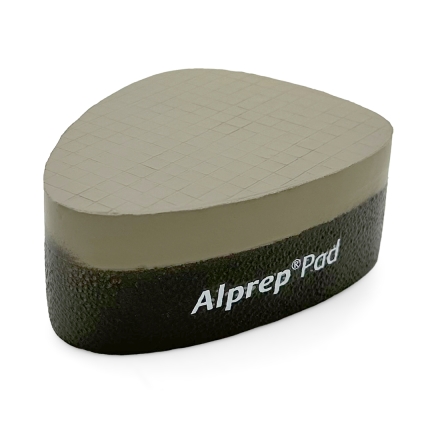

CUSTOMER SUPPLIED IMAGES

The marketing team at Spire Payments contacted us for a quote. At this stage all we required to provide a quote were the images of the product they wanted us to manufacture into a stress item. The client had some specific requirements with the shape which were that it had to be a life-sized replica of their product, and to have as much realistic detail as possible including raised buttons on the keypad.

RESIN MOCK-UP PRODUCED

With the quote approved, and the order placed the spec is sent to the factory, who then hand produce an initial resin prototype before any tooling is created. At this stage images were sent to the client for approval, with product dimensions (as per the pictures). The resin prototype was perfectly accurate for the clients requirements, so didn't require any changes, but changes to the prototype could've be made at this stage if necessary.

SAMPLES AND PRODUCTION

Once the resin prototype was approved, the factory then manufactured a handful of samples which were sent to the client for approval before mass production.

FINAL PRODUCT IMAGES

Manufacturing stress balls is quite time consuming... There's the physical product to manufacture, any excess needs to be trimmed, colours to be masked and sprayed, and then there's the printing too! So, a few weeks later, the stress credit card terminals were finished, individually poly-bagged, packaged and shipped over.

Client feedback

SEE THE FINISHED STRESS BALL VIDEO

SEE MORE CASE STUDIES

- SHOW ALL

- ELECTRONICS

- INDUSTRIAL

- TRANSPORT

- CHARACTERS

- ANIMALS

- MEDICAL

- ECLECTIC